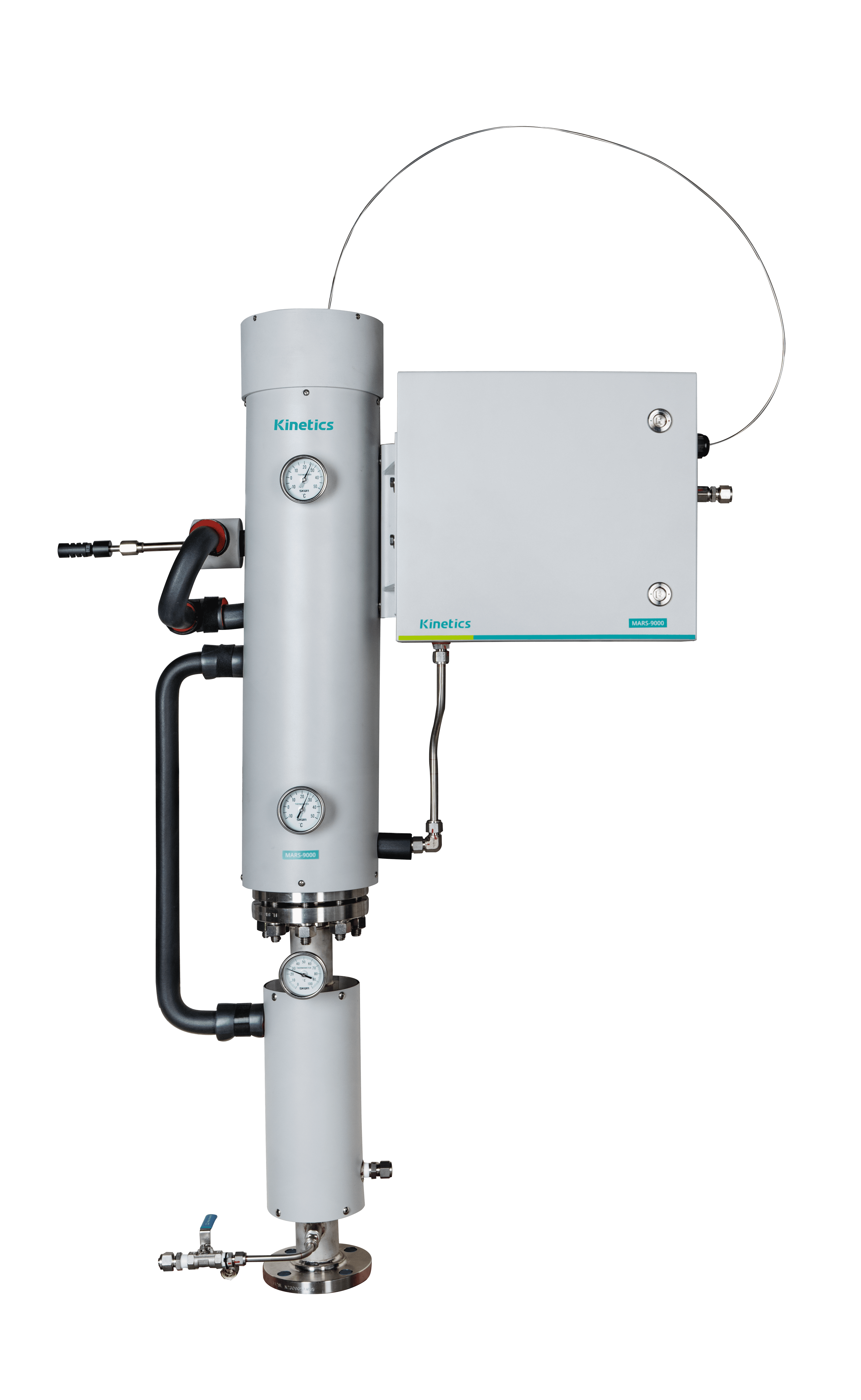

MARS-9000

模組化先進式返流取樣系統

Modular Advanced Reflux Sampler System

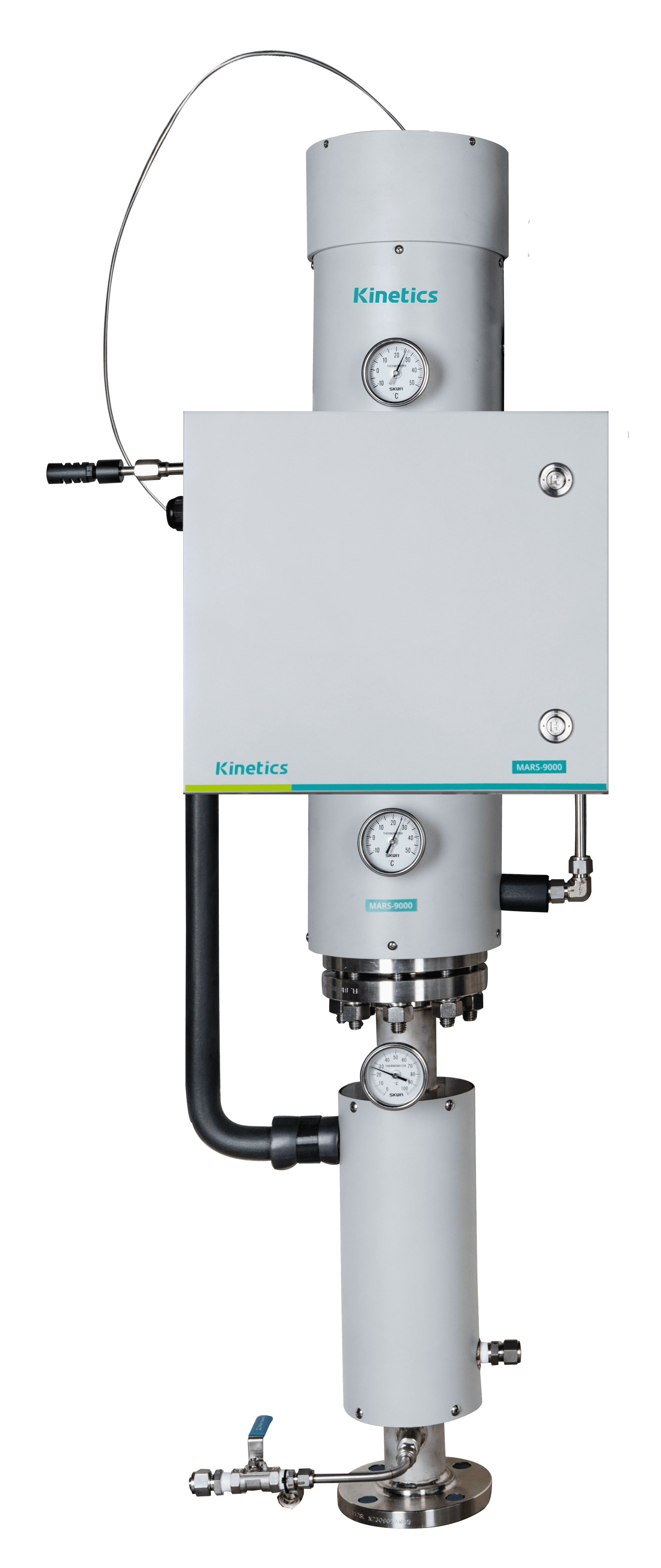

- 提供最佳樣品的完美選擇:專為分析儀和樣品調理系統提供清潔且均勻的樣品,確保客戶的測試結果準確可靠。

- 自我清潔,省心省力:獨特的自清潔設計,減少了維護的需求,降低營運成本。

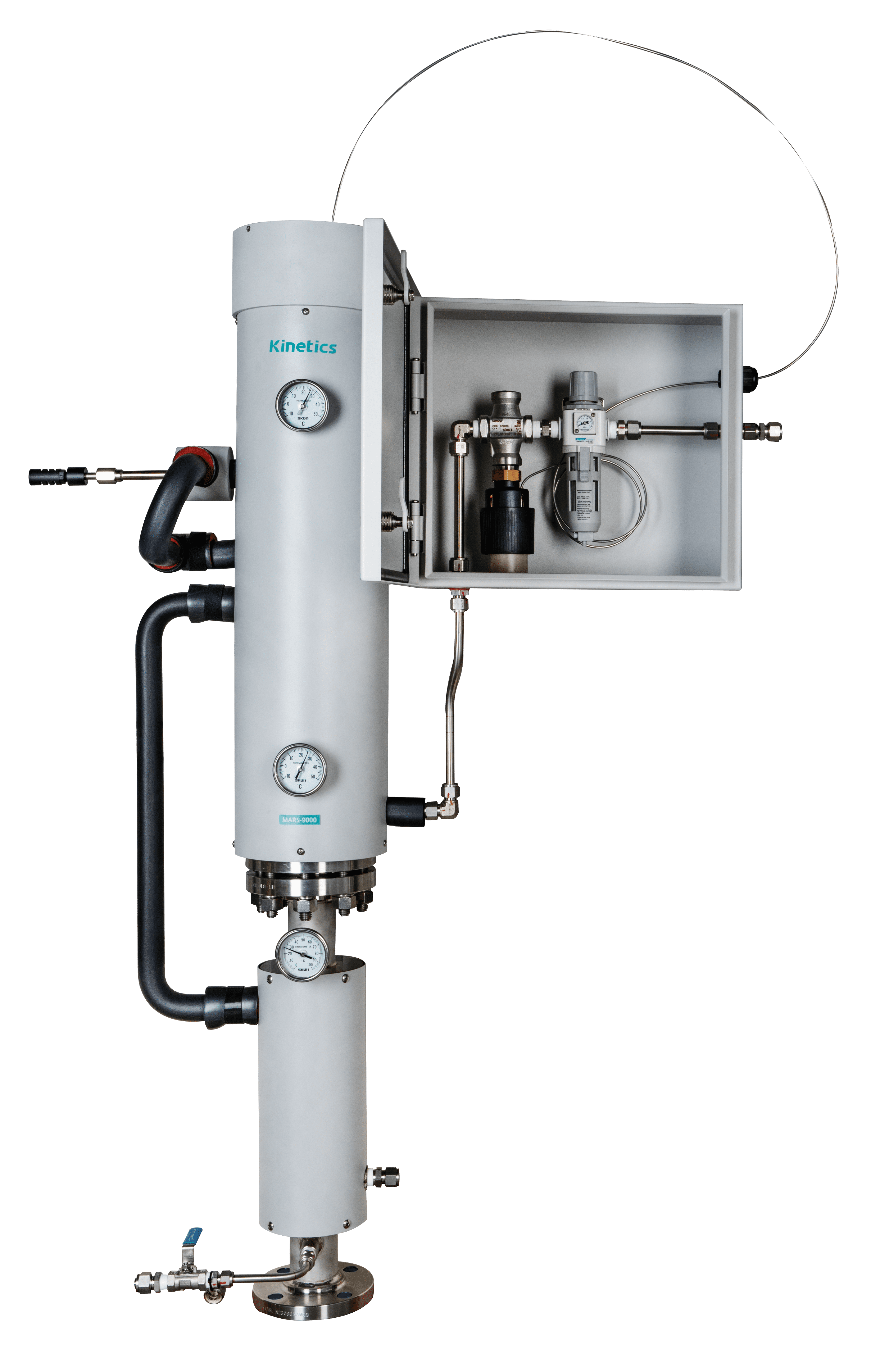

- 頂尖的冷卻技術:融合了渦流製冷器與壓縮空氣預冷設計,確保樣品維持在最佳的狀態。

- 專利的雙重冷卻通道:採用專利的雙重冷卻通道設計,維持穩定且充足的冷卻介質,確保代表性取樣。

- 考慮周全的保護設計:在樣品出口設有熱止閥(在 35℃時關閉),全方位保護客戶的下游設備。

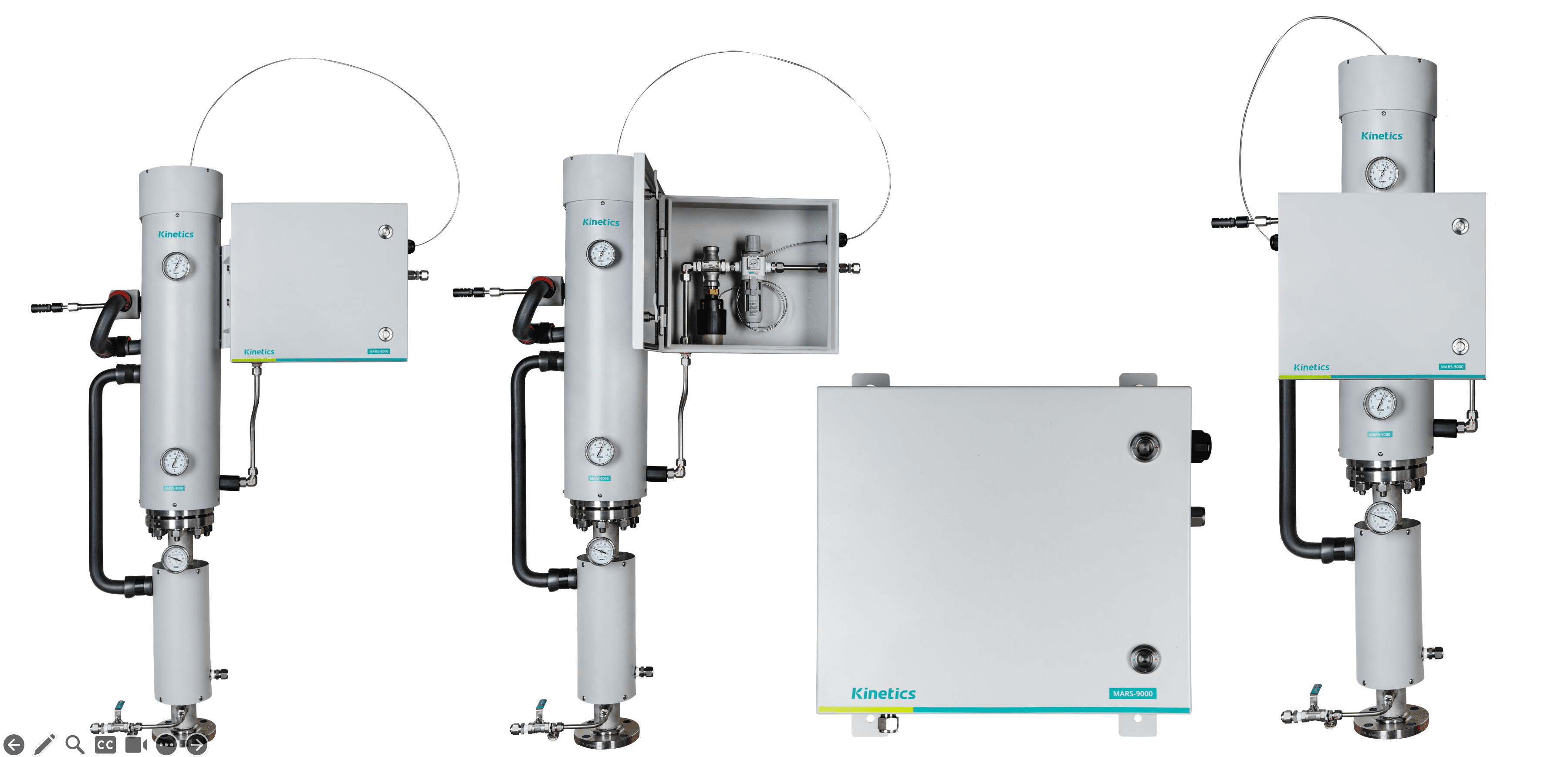

- 無轉動元件,壽命更長:降低了潛在的機械故障,使得設備使用壽命更長。

- 適用於危險區域:我們的產品設計無需電力,適用於危險區域,為客戶於作業上提供了極大的便利和安全保障。

睿普產品

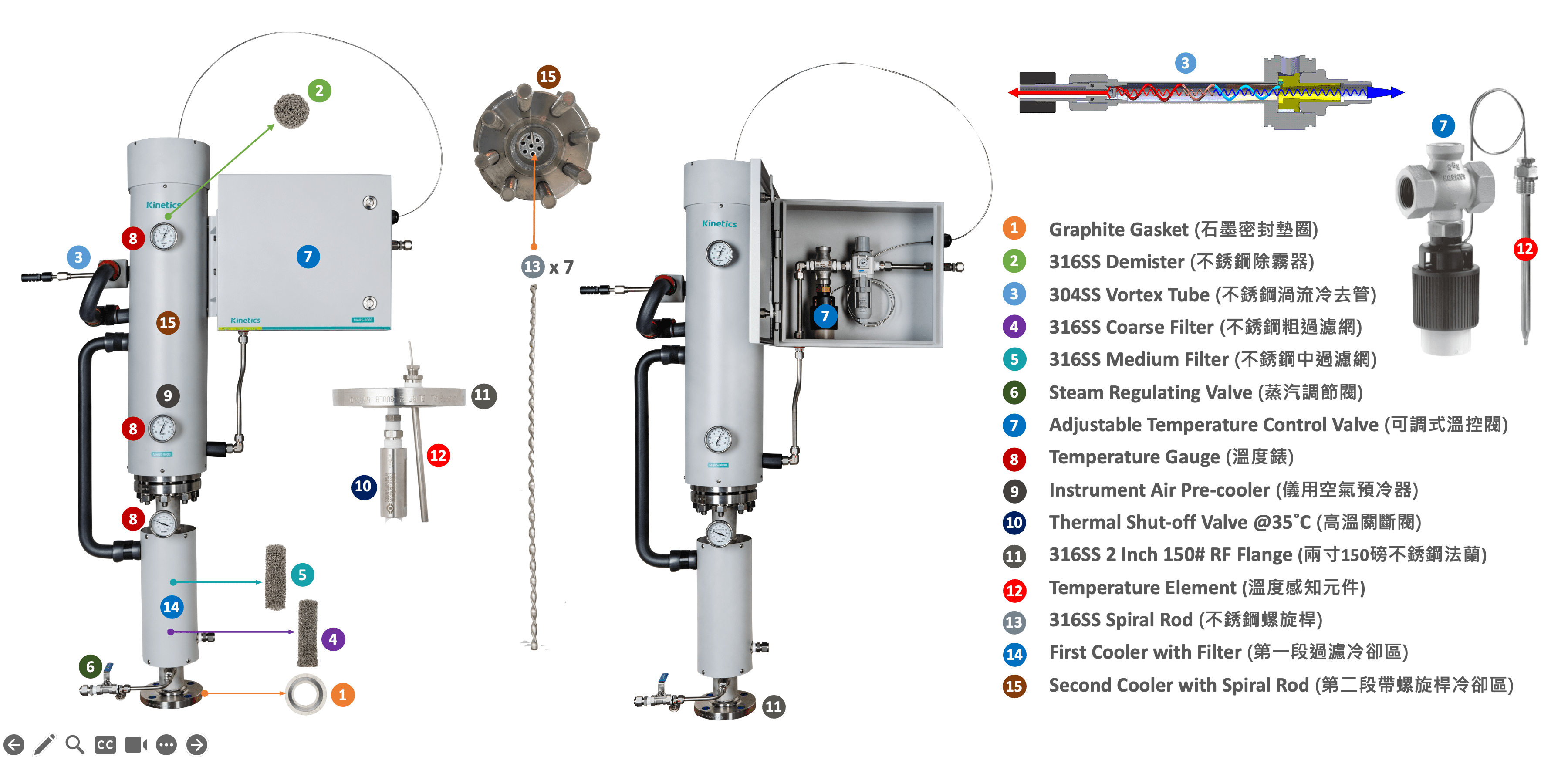

MARS-9000 是一款專為高溫、髒污、油氣製程管道取樣而設計的創新型反流取樣系統。它可取出具有代表性的氣體樣品,進一步由下游的分析儀器進行成分測量,如氣相層析儀和連續氣體分析儀(MGA-9000)。 MARS-9000 結合簡單的化學工程原理和受控的樣品速度和溫度差,能夠有效地去除高溫碳氫化合物氣體混合物中的液態霧氣、重質顆粒和細微碳粒,實現較輕的碳氫化合物的分析。

技術規格

型號

MARS-9000

操作原理

使用渦流冷卻器的過濾回流方式

主體及構造材料

全部為 316 不銹鋼

製程連接

ANSI 2" 300 # ( 如有其他需求,請諮詢我們進行訂製 )

樣品出口連接

1/4" NPTF ( 如有其他需求,請諮詢我們進行訂製 )

取樣入口溫度

40 ~ 750℃

取樣入口壓力

1.5 ~ 600 psig

樣品出口流量

1 ~ 5 LPM

樣品出口(露點)溫度

0 ~ 20 ℃ (視現場儀錶空氣壓力而定,可調整)

壓降

大約 1 psi,具體取決於操作和維護

預冷過濾區出口溫度

30℃ 以下

儀器空氣消耗量

227 ~ 650 升/ 分鐘@ 90 psig

安裝

垂直或水平安裝(允許± 5°的誤差)

重量

40 ~ 50 kg ( 取決於配置 )

專利證書.png)

專利證書_20230105.png)