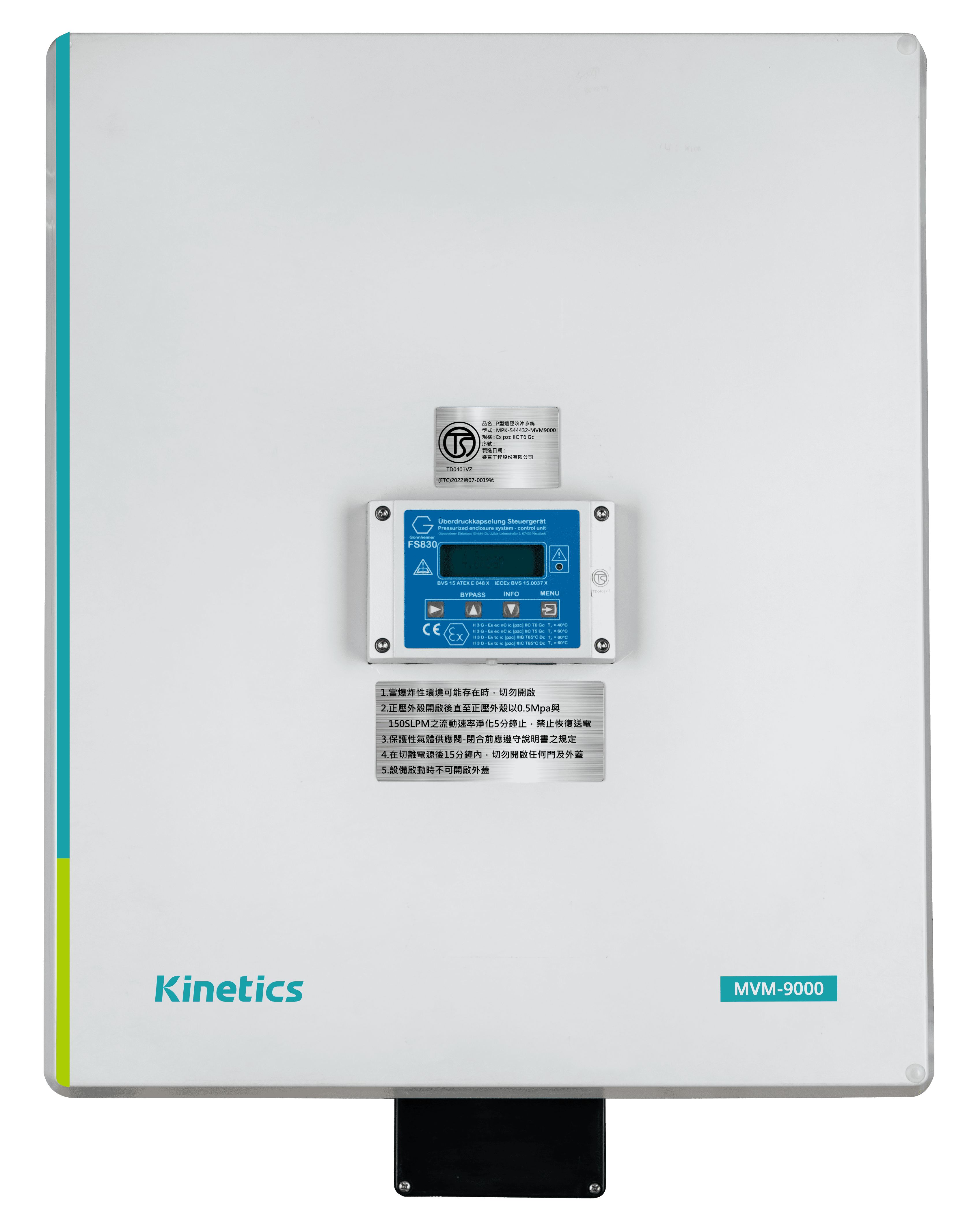

MVM-9000

模組化差壓式流速計

Modular Differential Pressure Type Velocity System

- 榮獲中華民國發明專利,證號:I762081 。

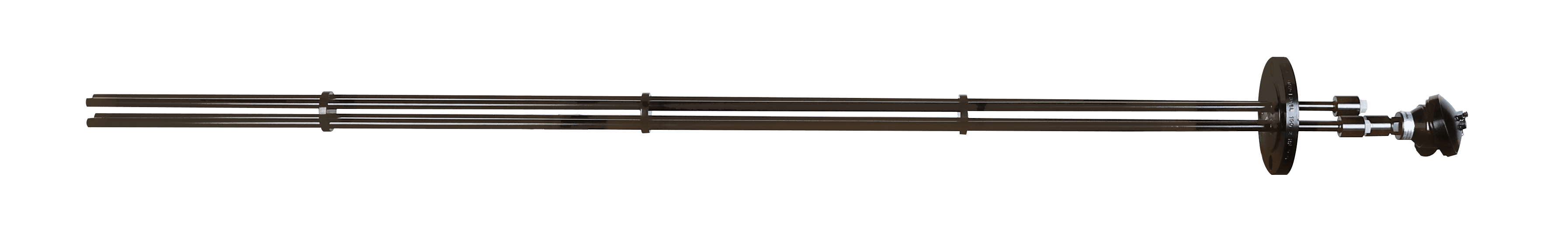

- 經現場測試證明,可在高達 950℃ 的 高溫下(視材料而定)完成可靠之排氣速度量測。

- 針對腐蝕性氣體的獨特設計,使用耐腐蝕材料或塗佈。

- 皮托管提供單端、雙端型式以滿足不同尺寸煙囪的需求。

- 獨特的多孔動態和靜態壓力量測設計,可以平均地測量煙囪或管道流量,並可直測煙囪壓力(選配)。

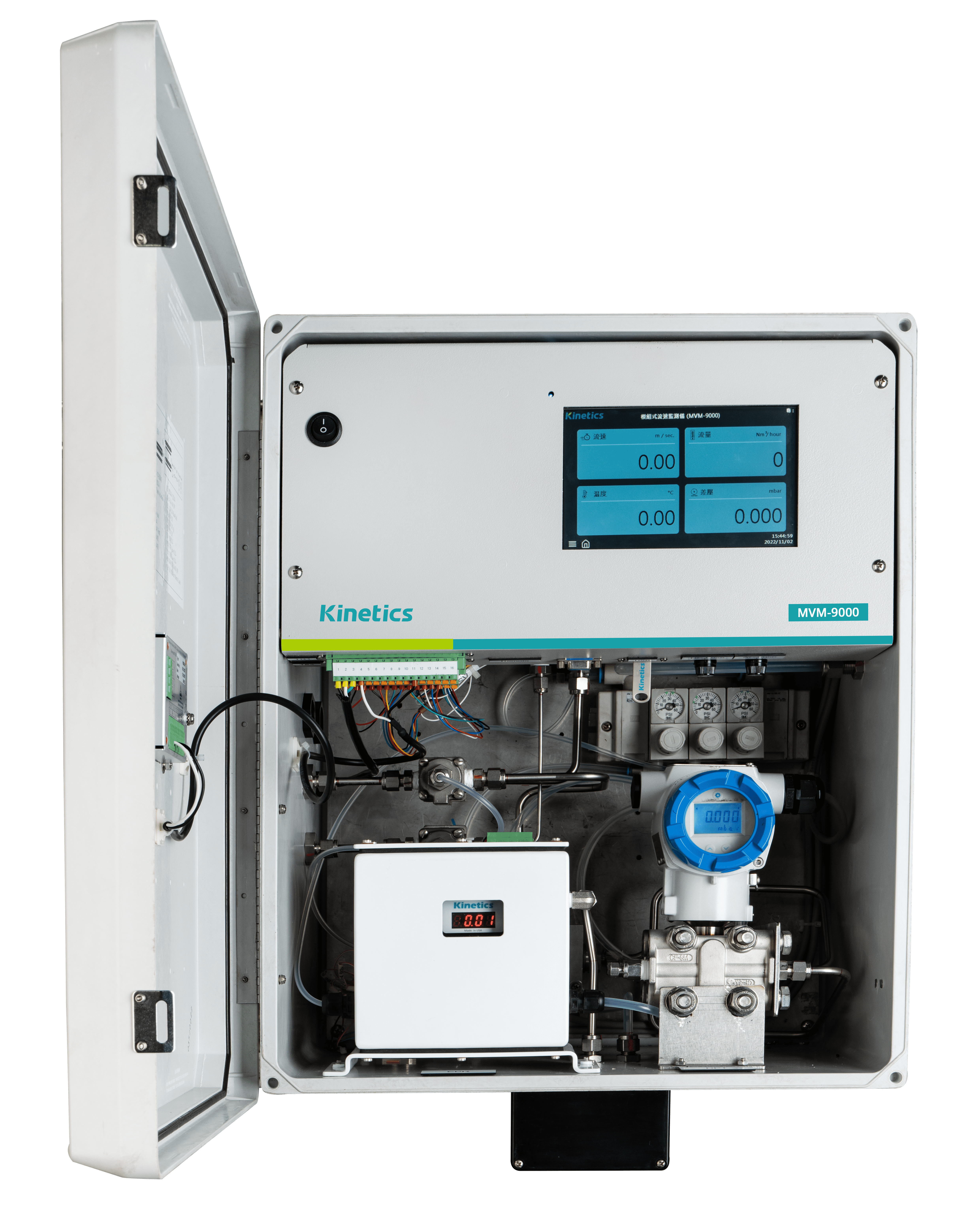

- 友善 UI/UX 介面的人機介面(HMI)。

- 創新的“真實”零點和全幅校正,無需額外的工具。

- 可調節的全幅校正範圍 。

- 創新的反吹和排氣設計 。

- 提供防爆選項,並已獲得勞動部 TS 防爆型式認證。

- 可以通過 SD 卡或 USB 外部存儲設備存儲超過三年的原始數據(測量或外部數據)。

- 支持可配置參數選擇的 4-20 mA 隔離類比輸出(包括外部輸入)。

- 標配 Modbus/TCP 協議和 RJ-45 乙太網路口的 OPC UA 。

- 提供無線操作選項(WiFi 和藍牙)。

睿普產品

MVM-9000 模組化差壓式流速計,榮獲中華民國發明專利(證號:I762081),是一款卓越且穩定的工具,特別為測量管道和 煙囪中的排放尾氣或製程氣體的流速和體積流量而設計。它擁有真實零點和全幅功能,並可直接量測煙囪壓力,極其適合於 連續排放監測系統(CEMS)的需求。利用先進的科技與設計,我們的差壓式流速計可以提供最準確的數據,同時提供高度的操作便利性。其模組化設計使得安裝和維護更加方便,並且可以完美適應客戶對流速計的特殊需求和期望。 無論是在煙囪廢氣監測、製程控制,還是空氣品質監測等多種工業應用中,此系統都能提供卓越且可靠的性能。我們的 MVM- 9000 模組化差壓式流速計,榮獲發明專利,無疑是客戶理想的選擇。

技術規格

型號

MVM-9000

測量原理

差壓式(Differential pressure)

測量範圍

0 ~ 2 至 0 ~ 100 m/s(根據現場應用選擇 適當範圍)MVM-9000 可基於相對煙道資訊和溫度計算流量。

煙囪壓力 ( 選配 )

0 ~ 1600 mBar abs.

最小檢測極限

根據測量範圍不同有所差異 ( 請與我們聯繫)

皮托管型式

標準材質為 316 不銹鋼,單端式設計,從法蘭總共延伸 1.5 米長度

系統箱操作環境溫度

0 ~ 60℃ , 99 % RH(無冷凝)

儲存溫度

-20 ~ 60℃ (無冷凝)

電源

100 ~ 240 VAC,50/60 Hz

功率消耗

280 VA Max.

設備需求

儀錶空氣(5 ~ 7 kg/cm2 ,-40℃ 露點)

防護等級

IP66/NEMA4X

機殼材料

FRP

尺寸(高 x 寬 x 深)

540 x 440 x 295 mm

重量

35 公斤

防爆(選配)

Ex pz IIC T6 Gc 並取得台灣 TS 型式認證,適用於 Zone2 的防爆區域

資料儲存

資料儲存時間長達三年,可以透過 SD 卡或 USB 隨身碟儲存與擴充

法規認證

符合美國 EPA 40CFR Part 60 和台灣 EPA CEMS 的要求

中華民國發明專利

No. I762081

-證書(i762081號).png)

證書.png)